Cartridge Filter (CF)

Cartridge filters were once considered only as a point-of-use water treatment method for removal of larger particles. However, breakthroughs in filter design, such as the controlled use of blown microfiber filters (as opposed to wrapped fabric or yarn-wound filters), have tremendously broadened cartridge filter utilization. Cartridge filters fall into two categories: depth filters or surface filters

Depth Cartridge Filters

In a depth cartridge filter the water flows through the thick wall of the filter where the particles are trapped throughout the complex openings in the medium. The filter may be constructed of cotton, cellulose and synthetic yarns, chopped fibers bound by adhesives, or “blown” microfibers of polymers such as polypropylene.

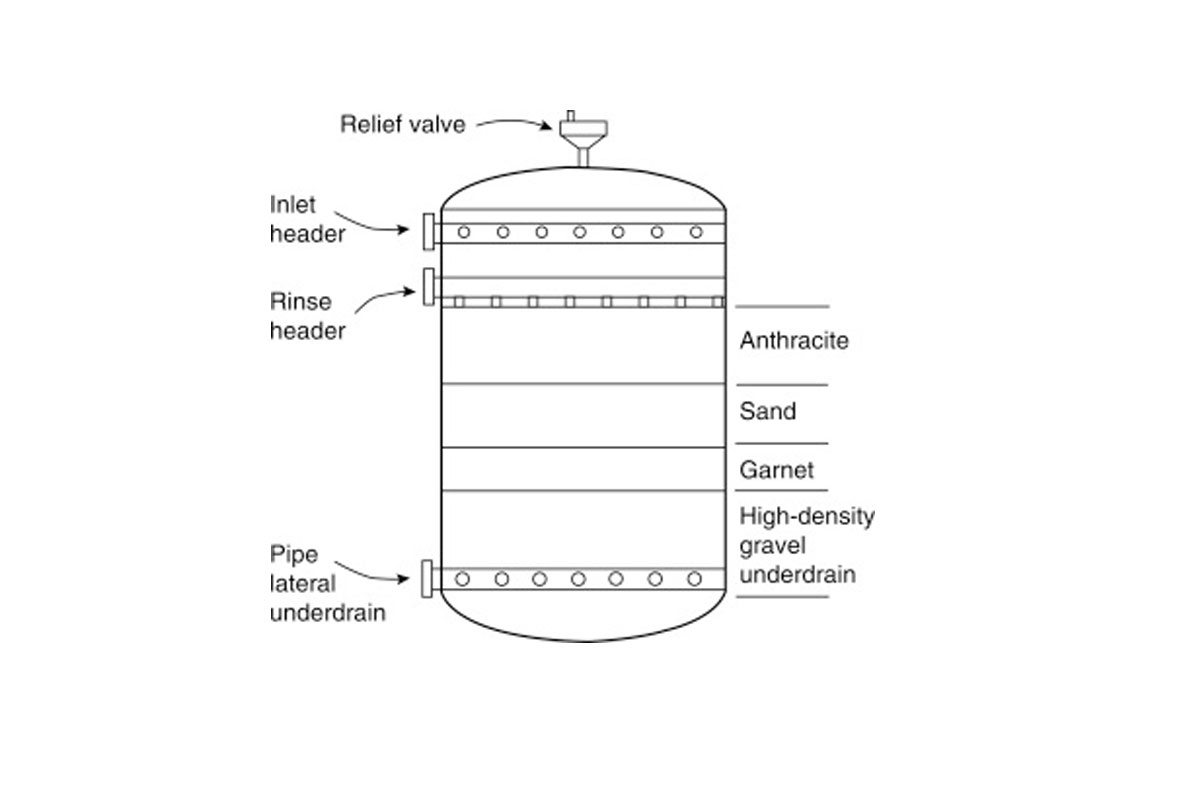

The most important factor in determining the effectiveness of depth filters is the design of the porosity throughout the thick wall. The best depth filters for many applications have lower density on the outside and progressively higher density toward the inside wall. The effect of this “graded density” (Figure 9) is to trap coarser particles toward the outside of the wall and the finer particles toward the inner wall. Graded-density filters have a higher dirt-holding capacity and longer effective filter life than depth filters with constant density construction.