For all levels of wastewater treatment, the last step prior to discharge of the sewage effluent into a body of surface water is disinfection, which destroys any remaining pathogens in the effluent and protects public health. Disinfection is usually accomplished by mixing the effluent with chlorine gas or with liquid solutions of hypochlorite chemicals in a contact tank for at least 15 minutes. Because chlorine residuals in the effluent may have adverse effects on aquatic life, an additional chemical may be added to dechlorinate the effluent. Ultraviolet radiation, which can disinfect without leaving any residual in the effluent, is becoming more competitive with chlorine as a wastewater disinfectant.

Sewage Treatment Plant (STP)

Sewage Treatment Plant

Domestic sewage is slightly more than 99.9 percent water by weight. The rest, less than 0.1 percent, contains a wide variety of dissolved and suspended impurities. Although amounting to a very small fraction of the sewage by weight, the nature of these impurities and the large volumes of sewage in which they are carried make disposal of domestic wastewater a significant technical problem. The principal impurities are putrescible organic materials and plant nutrients, but domestic sewage is also very likely to contain disease-causing microbes. Industrial wastewater usually contains specific and readily identifiable chemical compounds, depending on the nature of the industrial process. Storm sewage carries organic materials, suspended and dissolved solids, and other substances picked up as it travels over the ground.

The amount of putrescible organic material in sewage is indicated by the biochemical oxygen demand, or BOD; the more organic material there is in the sewage, the higher the BOD, which is the amount of oxygen required by microorganisms to decompose the organic substances in sewage. It is among the most important parameters for the design and operation of sewage treatment plants. Industrial sewage may have BOD levels many times that of domestic sewage. The BOD of storm sewage is of particular concern when it is mixed with domestic sewage in combined sewerage systems.

Dissolved oxygen is an important water quality factor for lakes and rivers. The higher the concentration of dissolved oxygen, the better the water quality. When sewage enters a lake or stream, decomposition of the organic materials begins. Oxygen is consumed as microorganisms use it in their metabolism. This can quickly deplete the available oxygen in the water. When the dissolved oxygen levels drop too low, trout and other aquatic species soon perish. In fact, if the oxygen level drops to zero, the water will become septic. Decomposition of organic compounds without oxygen causes the undesirable odours usually associated with septic or putrid conditions.

There are three levels of wastewater treatment: primary, secondary, and tertiary (or advanced). Primary treatment removes about 60 percent of total suspended solids and about 35 percent of BOD; dissolved impurities are not removed. It is usually used as a first step before secondary treatment. Secondary treatment removes more than 85 percent of both suspended solids and BOD. A minimum level of secondary treatment is usually required in the United States and other developed countries. When more than 85 percent of total solids and BOD must be removed, or when dissolved nitrate and phosphate levels must be reduced, tertiary treatment methods are used. Tertiary processes can remove more than 99 percent of all the impurities from sewage, producing an effluent of almost drinking-water quality. Tertiary treatment can be very expensive, often doubling the cost of secondary treatment. It is used only under special circumstanc

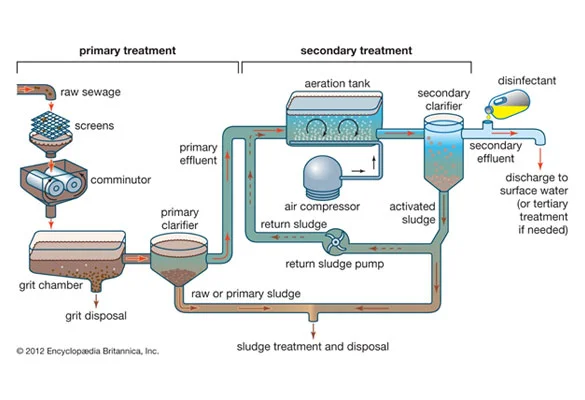

Primary Treatment:

Primary treatment removes material that will either float or readily settle out by gravity. It includes the physical processes of screening, comminution, grit removal, and sedimentation. Screens are made of long, closely spaced, narrow metal bars. They block floating debris such as wood, rags, and other bulky objects that could clog pipes or pumps. In modern plants the screens are cleaned mechanically, and the material is promptly disposed of by burial on the plant grounds. A comminutor may be used to grind and shred debris that passes through the screens. The shredded material is removed later by sedimentation or flotation processes.

Grit chambers are long narrow tanks that are designed to slow down the flow so that solids such as sand, coffee grounds, and eggshells will settle out of the water. Grit causes excessive wear and tear on pumps and other plant equipment. Its removal is particularly important in cities with combined sewer systems, which carry a good deal of silt, sand, and gravel that wash off streets or land during a storm.

Suspended solids that pass through screens and grit chambers are removed from the sewage in sedimentation tanks. These tanks, also called primary clarifiers, provide about two hours of detention time for gravity settling to take place. As the sewage flows through them slowly, the solids gradually sink to the bottom. The settled solids—known as raw or primary sludge—are moved along the tank bottom by mechanical scrapers. Sludge is collected in a hopper, where it is pumped out for removal. Mechanical surface-skimming devices remove grease and other floating materials.

Secondary Treatment:

Secondary treatment removes the soluble organic matter that escapes primary treatment. It also removes more of the suspended solids. Removal is usually accomplished by biological processes in which microbes consume the organic impurities as food, converting them into carbon dioxide, water, and energy for their own growth and reproduction. The sewage treatment plant provides a suitable environment, albeit of steel and concrete, for this natural biological process. Removal of soluble organic matter at the treatment plant helps to protect the dissolved oxygen balance of a receiving stream, river, or lake.

There are three basic biological treatment methods: the trickling filter, the activated sludge process, and the oxidation pond. A fourth, less common method is the rotating biological contactor.

Tertiary Treatment:

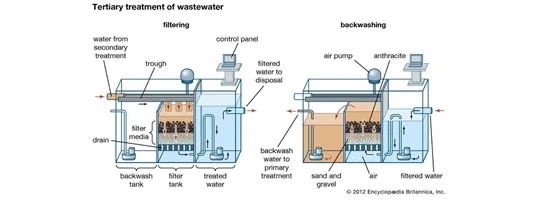

When the intended receiving water is very vulnerable to the effects of pollution, secondary effluent may be treated further by several tertiary processes.

Effluent polishing

For the removal of additional suspended solids and BOD from secondary effluent, effluent polishing is an effective treatment. It is most often accomplished using granular media filters, much like the filters used to purify drinking water. Polishing filters are usually built as prefabricated units, with tanks placed directly above the filters for storing backwash water. Effluent polishing of wastewater may also be achieved using microstrainers of the type used in treating municipal water supplies.

Types of Biological Treatment Technologies:

Anaerobic Treatment:

Anaerobic Treatment is an energy-efficient process in which bacteria transforms organic waste in the wastewater into biogas in the absence of oxygen. To achieve this oxygen-free environment, the entry of air into anaerobic tanks is prevented, typically by a gastight cover.

Upflow Anaerobic Sludge Blanket (UASB):

Upflow Anaerobic Sludge Blanket (UASB) technology, also known as UASB reactor is a form of an anaerobic digester that is used for wastewater treatment. In this process, wastewater flows upward through the blanket of sludge and microorganism degrade the organic matter and produces methane gas as a by-product, which further can be used as fuel.

Aerobic Treatment:

Aerobic is the process in which microorganisms convert organics waste into carbon dioxide and new biomass in the presence of oxygen. Aerobic treatment requires continuous oxygen supply so forced air from air blowers is mixed with the wastewater, where the aerobic bacteria feed on the waste in the water.

Activated Sludge Process (ASP):

In the ASP process, microorganism thoroughly mixed with organic compounds contained in wastewater under such conditions that stimulate their growth. As the microorganisms grow and are mixed by the agitation of the air, the individual organisms flocculate to form an active mass of microbes called activated sludge that derives the name of the process as ‘Activated Sludge Process’.

In a conventional activated sludge process, the wastewater is typically aerated for six to eight hours in a long, rectangular aeration basins. Sufficient air is provided to keep the sludge in suspension. The air is injected from the bottom through a system of diffusers.

Sequential Batch Reactor (SBR):

SBR is an application of ASP that is operated on a batch basis. It is used in small communities where space is limited. The design principles for this reactor are keyed to the following treatment steps: Fill: During this phase, the basin receives influent wastewater React: During this phase aeration and mixing units are on Settle: Air and mixing are turned off. The activated sludge is allowed to settle

Moving Bed Biofilm Reactor (MBBR):

MBBR is an economical and efficient solution for wastewater treatment. MBBR system consists of an aeration tank containing special plastic elements called media, to support the growth of biofilm in the reactor. These media have a large surface area for optimal contact with water, air and bacteria. The bacteria grow on the surface of the media and break down the organic matter from the wastewater. It significantly increases the capacity and efficiency of the existing plant and decreases the carbon footprint.

Membrane Bioreactor (MBR):

MBR is used in biological treatment with membrane separation. Membrane Bioreactor consists of a biological reactor with suspended biomass and solids separation by Microfiltration(MF) or Ultrafiltration(UF) membranes.